The EMERGENCE cemented cup respects the fundamental of the LFA (low friction arthroplasty) described by Sir John Charnley in 1962:

- ultra high molecular weight polyethylene arthroplasty

- reduced bearing diameter of 22.2mm or 28mm

- wide articulating chamfer in the lower quadrant of the cup favoring the ROM

- deep concentric grooves for a long-term fixation to the bone cement

- polar cylindrical contact allowing to preserve an even cement mantle around the cup

- peripherical flange of diameter larger than the dome

- peripheral crenels allowing the pressurization of the cement

- circomferential radiloucent wire

- holding and implantation instrument indexed to the cup

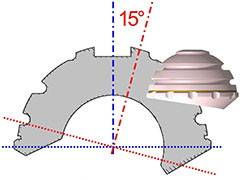

EVOLUTIS has brought 2 modifications to the original concept:

- a version of the articular plan of 15 ° with regard to the equatorial plane of the cup

- a PEXEL grade polyethylene (moderately crosslinked) which allows for a reduction of 50 % of the wear with compared with a conventional polyethylene

MOONSTONE bipolar cups are mechanically assembled in clean room to guarantee a high level of cohesion between the polyethylene liner and the metal shell, and a perfect cleanliness of the assembly.

MOONSTONE cups are available:

- in constrained version by deformation or with a locking ring,

- in inner diameter 22.2 or 28mm (28mm from the outer diameter 43mm)

- in “odd” outer diameter by bimillimetric increments in sizes 41 to 59 (43 to 59 in constrained version by deformation)

- in “even” outer diameter by bimillimetric increments in sizes 42 to 56 only in version with a locking ring

The MOONSTONE cups are made of stainless steel according ISO 5832-1 (shell) and UHMWPE according ISO 5834-1 & 2

Cementlessacetabular cup for total hip arthroplasty.

The Captiv FREELINER acetabular cup for Total Hip Arthroplasty is designed for cementless fixation to the bone, and enable 3 choices of friction bearing:

- moderately crosslinked PEXEL polyethylene against a metal or a ceramic head,

- highly-crosslinked polyethylene with vitamin-E (PEXEL -E) against a metal or a ceramic head,

- ceramic composite against a ceramic composite head.

The Captiv FREELINER cup has been designed to ensure maximum safety during implantation and security for the patient when used with either polyethylene or ceramic liners. The cup is uncompromisingly adapted to the different characteristics of these 2 bearings:

- the inner surface of the taper is smooth and free of asperities to facilitate and secure the insertion of the ceramic insert,

- the stability of the polyethylene insert is secured by 10 anti-rotational spurs and a locking ring situated on the equator.

Friction couples:

- Composite ceramic Ø32, 36 or 40

- Conventionnal “PEXEL” UHMWPE Ø28

- Highly Crosslinked “PEXEL-E” UHMWPE with vit-E(*) Ø32 or 36

Optimization of the diameters of the femoral heads:

- Ø32 friction couple as soon as the Ø46 cup

- Ø36 friction couple as soon as the Ø50 cup

- Ø40 friction couple as soon as the Ø54 cup

Insertion and fixation of the ceramic insert fully secured:

- Assembly and impaction of the insert in the cup made “on the instrument table” in a cly and dry environment

- Choice of straight or curved impaction shaft

- Conical seating of the ceramic insert in the cup without any asperity in order to limit any weakening of the ceramic integrity

- Circumpherential edge preventing the the stem neck to impinge on the ceramic liner

- Trials and implants matched with a clour code to ease and secure the intra-operative steps

Diameters and UHMWPE materials adapted to the indication:

- Conventional “PEXEL” 28mm UHMWPE liners including a posterior wall for the indications of total hip arthroplasty at the elderly

- Highly crosslinked E-vitamin “PEXEL-E” 32 and 36 UHMWPE liners(*) for the indications of total hip arthroplasty for the young and active patient

ACETABULAR CUP FOR POLYETHYLENE OR CERAMIC LINERS

Maximum security concept

The hard-on-hard friction couples require a thorough conception of the shell. The conical surface on which will be seated the liner, needs to be as smooth as possible and free of any peak stress inductors. The fitting of the liner into the shell need to be secured by a proper “taper entry” design, and the cup should prevent from micro-deformation under impaction stress, yet optimizing the head to cup diameter ratio.

On the contrary, the polyethylene liner will not be securely fixed based on a tapered connection alone. The polyethylene stability against rotation and pull-out stresses, need to be completed with mechanical devices such as ring locks and anti-rotational fins. In addition the liner needs to be protected from cold-flow deformation, and thus be perfectly adapted to the concavity of the cup.

Captiv OTM succeeds in combining both opposite requirements.

DESIGN RATIONALE

- primary hip arthroplasty elliptic acetabular cup

- moderately crosslinked PEXEL polyethylene or pure alumina or composite ceramic (Delta) choice of friction couple

- mechanical devices for polyethylene locking dissociated from the taper connection

- initial equatorial over-sizing increased by macrostructured design and 8 pairs of anchoring teeth

- hydroxyapatite coating 155 µm

- factory sealed screw holes to prevent wear particules migration

- apex hole plug included in packaging

Originally created in the mid 70’s by Professor Gilles BOUSQUET in St Etienne (France), the dual articulation acetabular socket rationale has kept improving since then, and offers nowadays a comprehensive solution to intra-prosthetic dislocation.

Indicated for primary arthritis patients above 70 years old, for femoral neck fractures whenever the patient is valid and active, for any patient presenting an important hip joint laxity, for patients with irrational behaviour, and for most hip revision cases, the dual mobility concept combines a high level of protection against dislocation and a controled and well documented polyethylene wear rate.

THE SOLUTION FOR ANY HIP ARTHROPLASTY WHEN POLYETHYLENE FRICTION IS CONSIDERED

CAPTIV DM is available in 2 versions :

- press-fit only, including an equatorial over-sizing macrostructure with 3 sets of anchoring teeth

- press-fit and dome spikes aimed at increasing the primary stability of the shell

Both versions have a dual coating of porous titanium and hydroxyapatite.

The liners, manufactured in mediumly crosslinked polyethylene (PEXEL), provide a positive excentration to the femoral head. This principle which consists in offseting the center of rotation of the femoral head from that of the liner, limit the contact and wear at the “third articulation” level: between the prosthetic neck and the inner lip of the liner. The positive excentration mechanism forces the liner to remain perpendicular to the femoral neck axis as soons as the body weight is applied through the joint and to the lower limb.

The liners are available for all sizes of cup in inner diameters 22.2 and 28mm. Optionally a ceramic sandwich liner, in clinical use for more than 5 years, is also available.